Rotational Molding Machinery: State-of-the-Art Equipment for Efficiency

Plastic material manufacturing is now a crucial part of different industries. It offers manufactured fantastic efforts to various job areas, for example automotive, sea, agriculture, and others. Together with the progression in modern technology, various functions of plastic-type material manufacturing have emerged. One of the most impressive and Rotomolding stylish versions is rotomolding, which has revolutionized the plastic materials business. In this post, we shall investigate everything you need to know of the rotomolding approach.

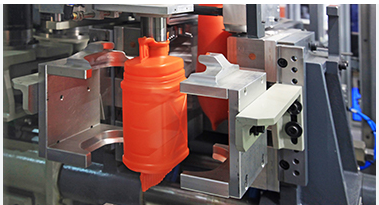

Rotomolding is an innovative approach employed to make complex plastic items. It demands molding the plastic-type material by heating and rotating it, allowing it to distribute evenly across the fungus work surface. This method is highly specific and creates high-top quality items with extraordinary style versatility. Rotomolding is useful for creating complex styles and elaborate designs of plastic material merchandise.

A single substantial advantage of rotomolding is that it can create products with seamless, consistent wall surfaces. Because of this the products’ thickness and strength are consistent, which leads to great-quality items. An additional advantage of rotomolding is that it can develop merchandise of various shapes and sizes, that makes it a popular option for diverse market sectors.

Additionally, rotomolding can make use of various kinds of thermoplastics. Polyethylene is regarded as the widely used thermoplastic within the rotomolding method due to its superb components like durability, chemical level of resistance, and flexibility. Additionally, rotomolding is setting-warm and friendly simply because it utilizes no chemicals or paints to produce merchandise.

Another significant good thing about the rotomolding approach is its charge-efficiency. When compared with other plastic-type material molding functions, the tooling and gear expense in rotomolding is pretty low. The straightforwardness in the procedure, consequently, decreases the manufacturing expenses. This benefit makes it a popular choice for small companies and commence-ups planning to produce substantial-good quality plastic goods.

Lastly, rotomolding also reduces squander by assisting the reuse of your raw fabric inside the manufacturing approach. As opposed to other molding functions, rotomolding can produce different goods from one mold, decreasing the demand for materials modify for each merchandise. This reduces the waste materials generated through the manufacturing process.

Simply speaking:

In Simply speaking, rotomolding is a revolutionary method that has significantly affected the plastic manufacturing industry. It offers several advantages such as the ability to produce elaborate models, longevity and consistency, charge-effectiveness, and enviromentally friendly friendliness. Because of these benefits, it is now a common option for creating plastic material goods across different industries. When you are thinking about manufacturing plastic merchandise, rotomolding needs to be the ideal selection.